Shanghai Hanbell was established in 1996 and listed on Shenzhen A-share market in 2007. Jinan, Guangzhou, Nanjing and Chongqing branches have been set up one after another, and the subsidiaries of Zhejiang Hanson, Shanghai Comer, Hanbell HongKong, Hanbell Vietnam, Hanbell Korea and Zhejiang Comer have been set up one after another. All these reflect the achievements of HANBELL people's hard work in the past 27 years.

HANBELL PRECISE MACHINERY COMPANY 27 YEARS OF HISTORYAIMS TO OPEN

From September 24 to 26, 2025, the 20th National Cold Chain Conference, hosted by the China Refrigeration and Air-Conditioning Institute (CRAA), was held in Haikou. With the theme of "Pioneer in Carbon Path, New Vitality in Digital Intelligence", this conference focused on the development opportunities of the cold chain industry and explored the new-quality productive forces of the future. Top industry experts, well-known design institutes, equipment manufacturers and end-users from all over the country participated in the conference. Hanbell Precision Machinery was invited to attend, jointly sharing industry trends, cutting-edge technologies, practical cases and innovative technologies, exploring new directions for the future development of cold chain logistics, aiming to create new models and opportunities and inject new vitality into the development of the industry.

On the morning of September 26, Li Neng, Specialist of Refrigeration Market Promotion at Hanbell Precision Machinery, delivered a keynote speech titled "How to Enhance the Core Competitiveness of Cold Storage through Technological Empowerment", in which he deeply analyzed the increasingly intensified market environment: "The continuous changes in market demand and national policies have put forward higher requirements for enterprises' independent R&D capabilities. Only by continuously optimizing products and providing more valuable solutions for the industry can enterprises achieve stable development in the cycle of intensified competition". He also analyzed the operation effects of Hanbell Precision Machinery's new technologies in the construction of multi-temperature-zone cold storage and quick-freezing equipment through practical cases.

At present, China is in the midst of unprecedented changes unseen in a century. The country has launched a series of policies such as the domestic and international dual circulation strategy, the 14th Five-Year Plan for Cold Chain Logistics Development, and the "dual carbon" goal (carbon peaking and carbon neutrality). The demand for energy conservation and consumption reduction in the refrigeration and freezing industry continues to rise, and systems that balance energy conservation, environmental protection and safety have become the demand orientation. How to select refrigeration systems and compressors has become one of the key considerations for various refrigeration and freezing projects to achieve green and low-carbon development as well as cost reduction and efficiency improvement. This key proposition is exactly the direction that Hanbell Precision Machinery has long been committed to: we always take energy conservation as the core R&D concept and make innovations to break through the industry's technological bottlenecks �� upholding the belief in energy conservation and continuously pioneering and innovating.

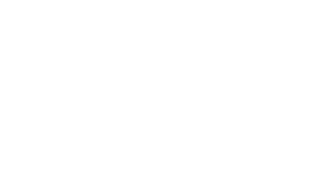

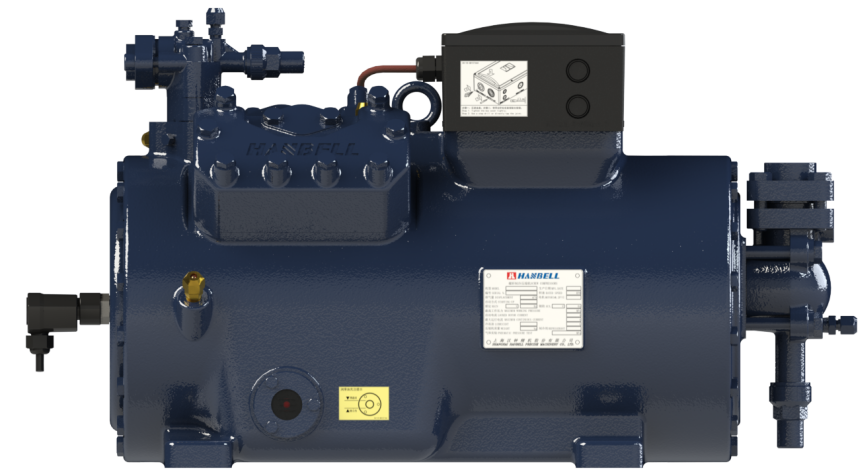

With the development of industries such as cold chain logistics and food processing, customers' demand for refrigeration screw compressors is no longer limited to a single refrigeration function, but is shifting towards green, high-efficiency and multi-functional features. For example, the rise of the fresh e-commerce industry requires compressors to have functions such as rapid cooling, precise temperature control and remote intelligent monitoring; the pharmaceutical cold chain field has extremely high requirements for temperature stability and equipment reliability. Hanbell Precision Machinery has always empowered cold chain logistics enterprises in the industry with the concept of energy conservation and high efficiency. In 2025, Hanbell Precision Machinery launched the new-generation LC Series semi-hermetic single-stage refrigeration & freezing screw compressors for variable-temperature storage and quick-freezing storage. This product adopts variable displacement ratio technology, enabling the compressor to maintain optimal performance when operating at the initial cooling stage and the designed temperature point, and achieving high-efficiency application under variable working conditions for both variable-temperature storage and quick-freezing storage. The flow channel and structure specially designed for low-temperature applications significantly reduce the noise and vibration of the compressor. It is equipped with a new integrated cloud-based protection module, which has functions such as oil flow protection and pressure difference protection, simplifying the unit control system while real-time monitoring the operation status of the compressor to ensure its normal operation.

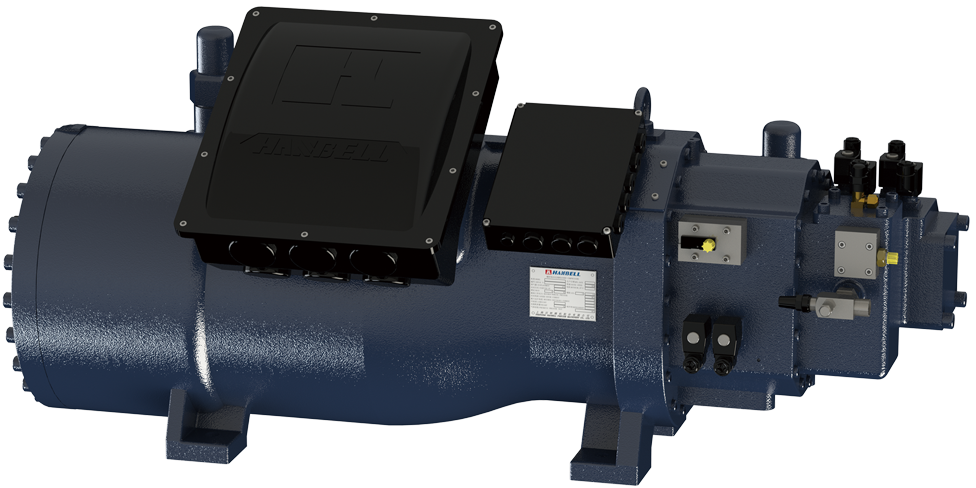

The second flagship product is the LTII-S-200/100-IVX (450 HP). Currently, the maximum capacity of Hanbell Precision Machinery's two-stage frequency conversion compressor can reach 450 HP, and its capacity can reach 4 tons in the application of quick-freezing single freezers. This means that semi-hermetic compressors can meet the large energy demand range of customers, making up for some shortcomings of open-type compressors. For instance, open-type compressors have the problem of shaft seal leakage, while semi-hermetic compressors have no shaft seal and do not require regular replacement. On the other hand, open-type compressors are large in size, require external motors and are complicated to use. In addition, open-type compressors need regular realignment due to vibration, which causes deviation after a period of operation and requires high technical skills of operators. Besides, this model is also equipped with a frequency conversion solution, and is sold as a whole with frequency converters and frequency conversion controllers, improving the reliability of frequency conversion technology and overall energy efficiency. Under quick-freezing working conditions, the comprehensive energy efficiency of the fully-configured two-stage frequency conversion compressors of the LTII-S-IVX series is approximately 20% higher than that of fixed-frequency two-stage compressors; under low-temperature refrigeration working conditions, the comprehensive energy efficiency is about 30% higher than that of low-temperature fixed-frequency single-stage compressors. It is suitable for quick-freezers and low-temperature refrigeration warehouses with higher energy-saving requirements, fundamentally improving the system energy efficiency, which has been verified by the application of many projects.

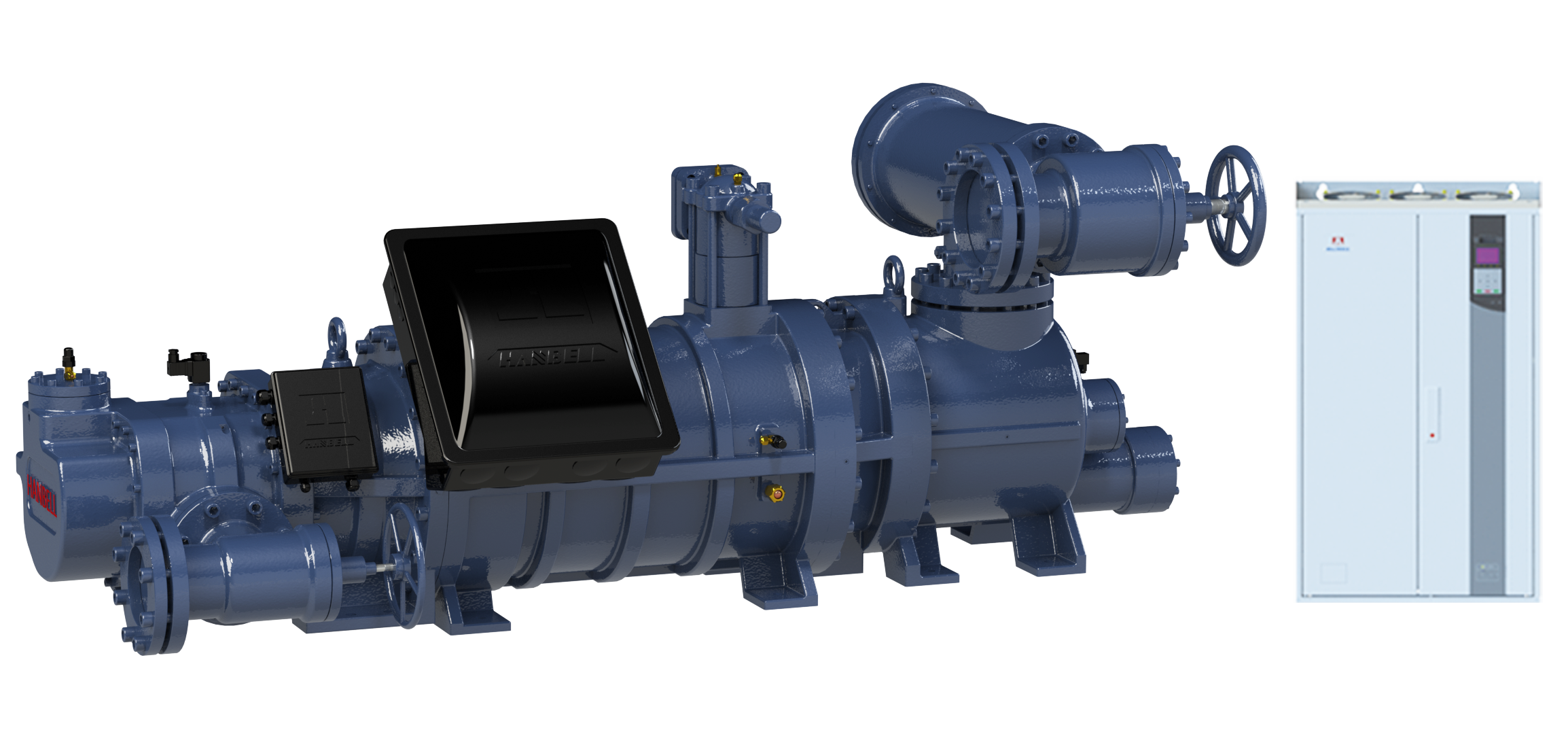

The third product is the new-generation RGII Series open-type single-stage refrigeration & freezing screw compressors, which are suitable for various refrigerants such as ammonia. Adopting a new tooth profile and structural design, its performance has been greatly improved; the new shaft seal structure design has significantly extended its service life. The product is equipped with a built-in middle bracket structure, which does not require alignment, ensuring easy installation and maintenance. The product is subdivided into M sub-series and L sub-series to meet the application needs of different working conditions. It has a built-in economizer stop valve and built-in discharge check valve design, simplifying the configuration of the system's fluorine pipeline. The variable displacement ratio design meets the needs of users under different working conditions and ensures efficient and stable operation at all times. The energy slide valve can be adjusted steplessly to provide cooling capacity according to user needs and save electricity. It is equipped with built-in system accessories such as oil filters, oil flow switches and pressure difference switches, simplifying the configuration of the system's oil pipeline. A new integrated protection module is adopted, which has functions such as oil flow protection and pressure difference protection, simplifying the system control system.

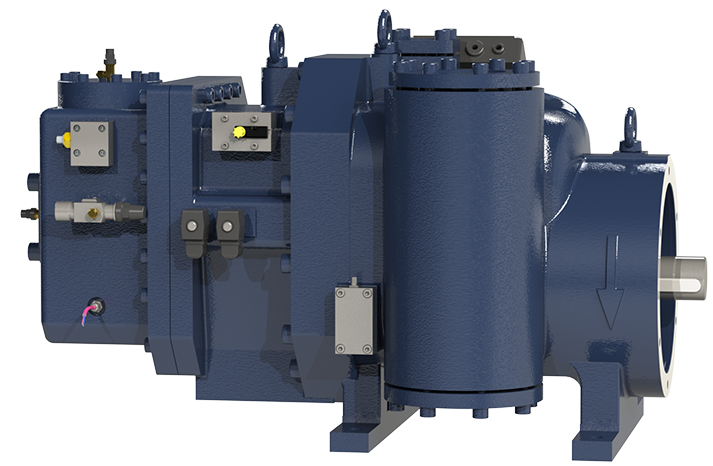

The fourth product is the LR Series semi-hermetic piston compressors, which focus on segmented scenarios with relatively small refrigeration capacity demands. Their applications cover supermarket refrigerators, commercial freezers, small cold storage, ice-making and freeze-drying equipment, supporting equipment for quick-frozen food processing, marine refrigeration systems and low-temperature environmental test devices, accurately matching the high-efficiency refrigeration needs in small cooling capacity scenarios. This series of products is subdivided into M sub-series and L sub-series: the M sub-series is suitable for medium and high-temperature working conditions, while the L sub-series focuses on low-temperature working conditions, meeting the application needs of different working conditions. The design of an enlarged oil sump structure improves the reliability of oil supply. The low oil throw rate design effectively extends the oil running time and significantly improves the operation stability. The high-strength shell design reduces operation noise and vibration. The enlarged flow channel space design reduces airflow pulsation and pressure drop. The sliding-matching motor design allows the motor to be replaced by removing the motor end cover, making maintenance and installation more convenient. An optional capacity-adjusting solenoid valve is available for more convenient cooling capacity adjustment. In addition, the product has been strengthened in terms of safety and intelligent configuration: the high-strength flame-retardant junction box is made of PA6 material (with strength much higher than that of traditional PC material), meeting the flame-retardant standard of no less than Class V0 and not being brittle in low-temperature environments. All models are equipped with motor temperature protection as standard, and optional discharge temperature protection is available. All models can be optionally equipped with pressure relief valves, which effectively reduce potential safety hazards and ensure normal discharge pressure operation. The oil heater, verified by rigorous dry-burning tests, further ensures the safety and reliability of the product. At the same time, it supports the optional integrated electronic oil level valve to realize the intelligent upgrade of oil level monitoring.

In recent years, Hanbell Precision Machinery has significantly increased its investment in low-temperature products, conducting product R&D and upgrading based on the concept of scenarioization. It provides differentiated solutions for different scenarios and user needs to meet the current market demand. In addition to continuous product upgrading, Hanbell Precision Machinery is also actively expanding overseas markets to improve its international service level and influence, aiming to provide complete compressor energy-saving application solutions for industries such as cold storage. We will continue to work hand in hand with partners to provide cold storage application solutions that improve quality and reduce consumption, create value, and contribute to the healthy development of the cold storage industry!